purenite boxes

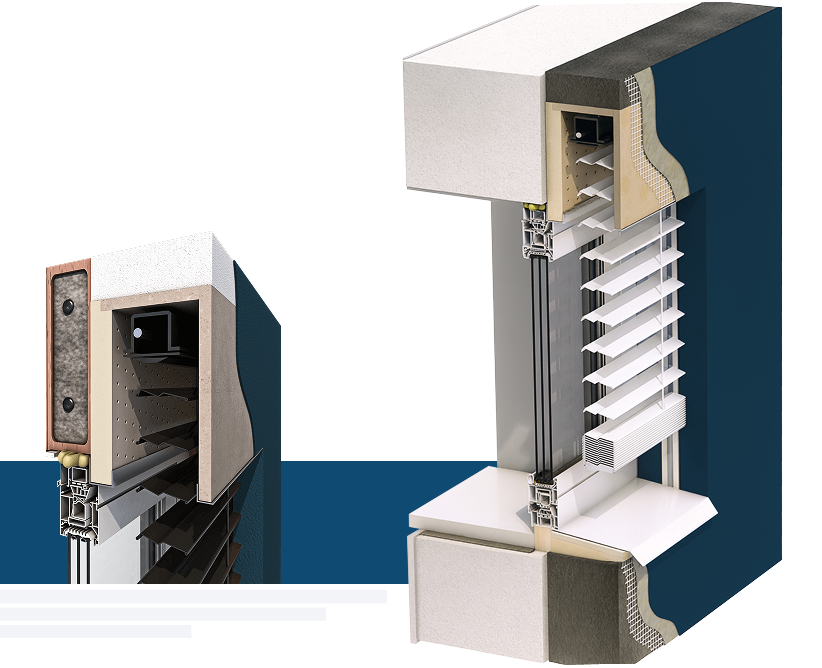

What are purenit boxes and what is their purpose?

Their main task is:

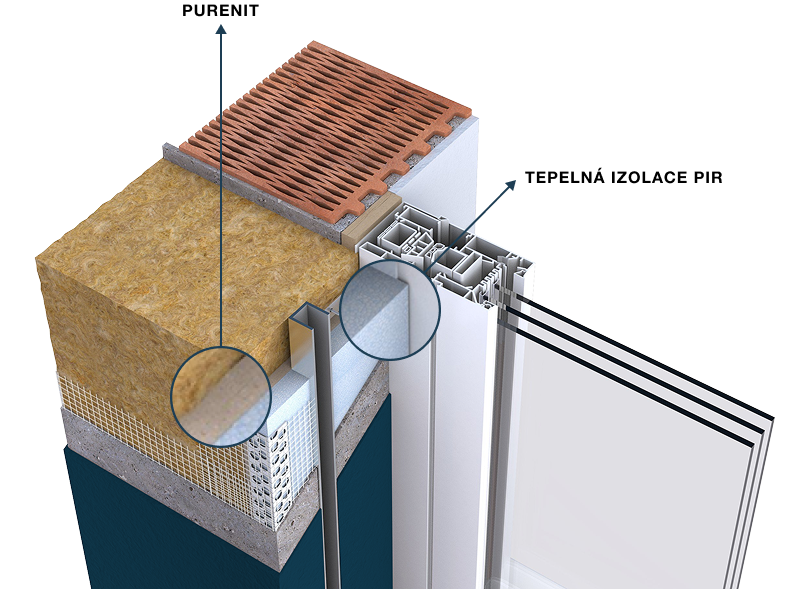

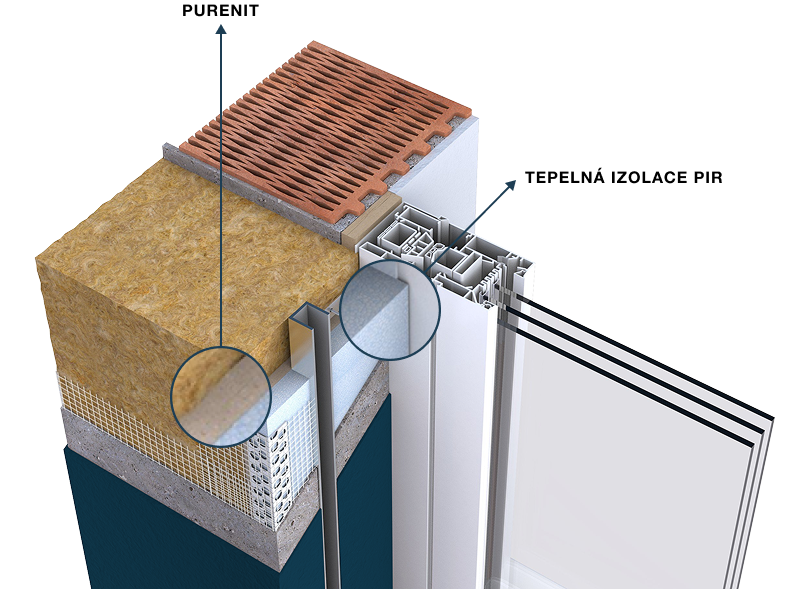

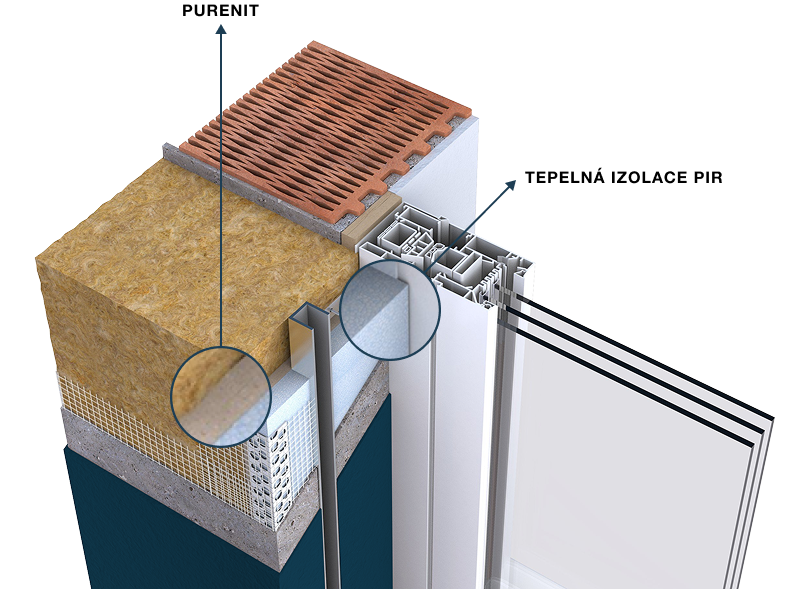

- to create space for shading technology without interfering with the appearance of the facade,

- to maintain a continuous thermal insulation layer at the installation site and thus prevent the formation of thermal bridges,

- to protect the structural detail from moisture penetration and loads during the installation and operation of shading technology.

Thanks to their high strength, dimensional stability and resistance to climatic influences, Purenit boxes are suitable for new buildings, reconstructions and energy-saving buildings.

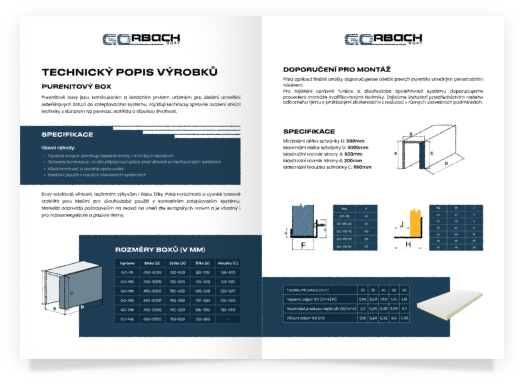

Types of boxes

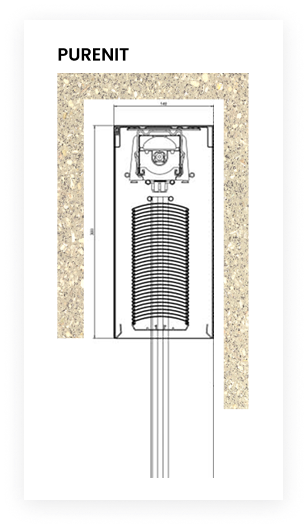

GO-PBI

Purenit box with insulation.

Insulation widths: 30 / 40 / 50 / 60 mm

The most commonly used variant with an emphasis on thermal insulation properties

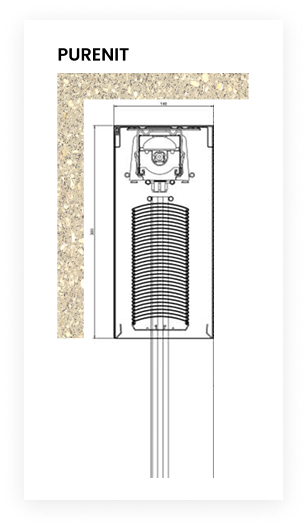

GO-PB

U-shaped box made of purenite. Used in cases where the lintel insulation is already provided. Compatible with KZS and allows standard connection of shielding technology

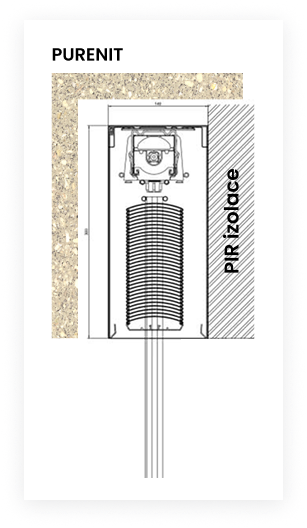

GO-PBL

L-shaped box made of purenite. Minimizes the thickness of the structure while maintaining function and aesthetics. Fully integrates shading technology without interfering with the facade design.

Types of boxes

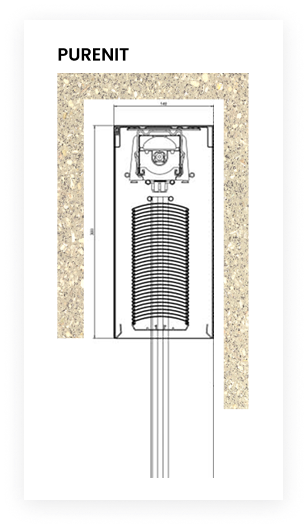

GO-PBI

Purenit box with insulation.

Insulation widths: 30 / 40 / 50 / 60 mm

The most commonly used variant with an emphasis on thermal insulation properties

GO-PB

U-shaped box made of purenite. Used in cases where the lintel insulation is already provided. Compatible with KZS and allows standard connection of shielding technology

GO-PBL

L-shaped box made of purenite. Minimizes the thickness of the structure while maintaining function and aesthetics. Fully integrates shading technology without interfering with the facade design.

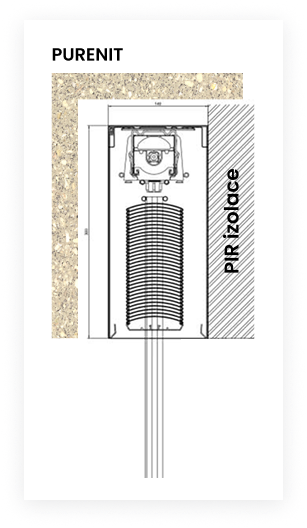

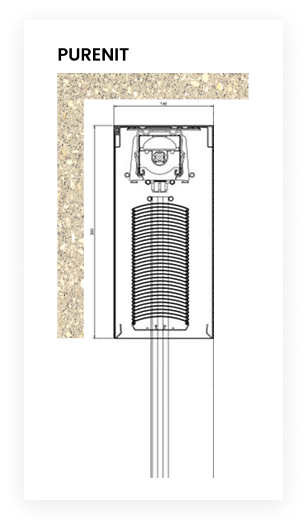

PURENITE INSULATION LINERS

Purenit lining is a structural element designed for concealed installation of guide rails for exterior blinds in the facade. The lining is made of technically stable Purenit material, resistant to moisture, temperature fluctuations and mechanical stress.

Why is it important

- Concealed slat guidance – an aesthetically clean detail without visible elements on the facade.

- Breaking thermal bridges – ensures a continuous thermal insulation layer and minimizes heat loss.

- Structural stability – a solid base for precise installation of guide rails.

Installation and service

We are not just a supplier – we are a partner who takes care of the entire process from design to final installation. Our experienced technicians will ensure professional installation of Purenit boxes and insulation lining directly on your project, in accordance with project documentation and technological standards.

- Professional design - precise installation for long life and flawless system functionality.

- Save time – no need to coordinate multiple suppliers.

- Quality guarantee – we stand behind the result and provide a full guarantee for our work.

Detailed technical information about installation procedures can be found in our catalog – including recommended installation options, anchoring elements and examples from implementations.

ONE COMPANY, TWO SOLUTIONS

Stage 1 – Preparation and insulation

We will ensure our own construction preparation without dependence on facade contractors

Stage 2 – Box assembly

Quick and accurate installation of the window box

Stage 3 – Facade

After agreement, we will carry out the final facade work.

Stage 4 – Blinds and modifications

Installation of blinds and implementation of client changes